Image

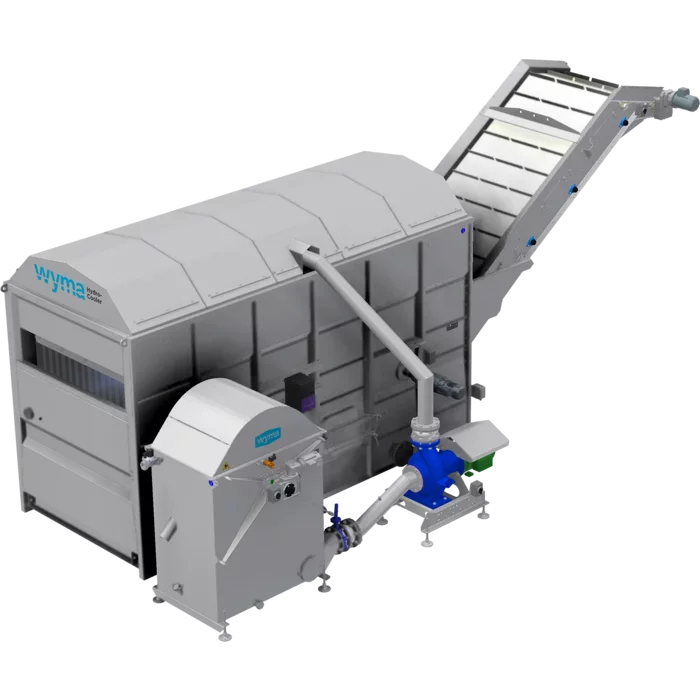

Evenflow

The Evenflow Hopper is a combination conveyor and hopper. It evenly supplies produce on-demand to the next stage in the line, converting an irregular infeed into a constant outfeed flow. It can also provide buffer storage. The Evenflow Hopper starts in a raised position with the infeed end of the conveyor bed as high as it can go. When a sensor detects produce on the conveyor, the end lowers, creating a storage area. As produce backlog clears, the end of the conveyor lifts back up.

Most Common Uses

- Carrots

- Onions

- Potatoes

Wyma Evenflow

Product Detail

Features

- Large storage capacity (approximately 650 - 2,200 lbs)

- Produce can be stored before it is fed to the line

- Two geared motors – one for conveyor and one for lift action

- Produce depth sensor helps minimize infeed drop

- Variable speed conveyor for feed rate control

- Heavy-duty belt

- Simple, durable tensioning system

- Adjustable feet for easy, level installation

- Automatic conversion from hopper to conveyor for flexible application

Available Options

Brochures & Product Documents

Ordering

To order call 1-800-253-4737 or email equipment@volmcompanies.com for more information.