We Have A VESTed Interest In You

With the Volm VEST team, iteration beats incremental. Here’s why.

Typical packing facility design or new equipment integration takes an incremental approach that takes stock of what you’ve already got and what you need, and then works to reconcile the two. The Volm Engineered Solutions Team (VEST) takes a more effective Iterative Refinement Design approach that enables a smarter, more cost-effective design and implementation process.

How VEST Works

1. Project Request Evaluation

This first step gets the whole thing started by gathering all necessary information to determine whether the Volm VEST team is the best solution for your specific challenges.

2. Flash Assessment

- Identify key drivers/goals of the project

- Determine the project’s “must haves” and “nice to haves”

- Fully understand budget constraints

- Develop timeline parameters

Phase Deliverables:

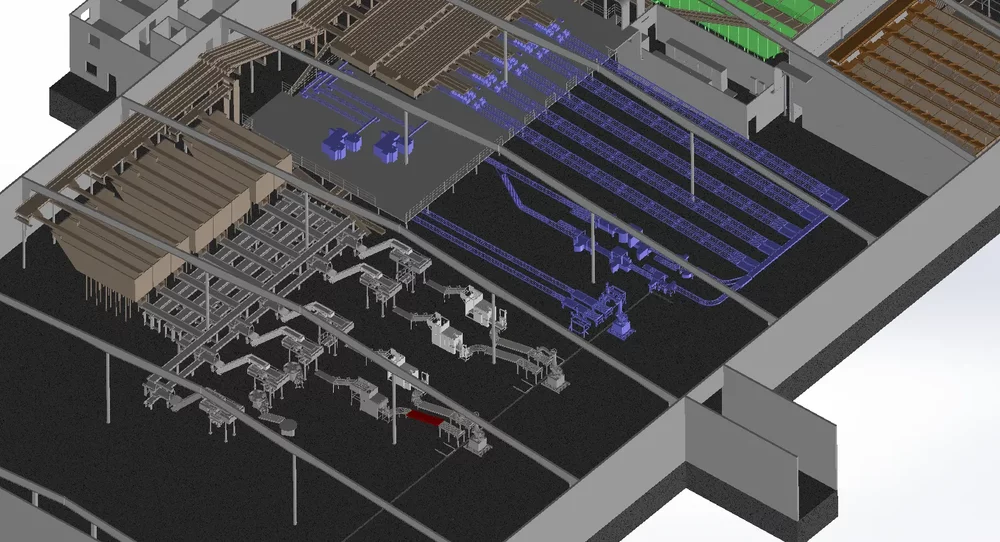

- Sample project layouts

- Project budget estimates

3. Engineering Study

- Determine the functional requirement for the project

- Develop and agree on initial concept designs

- Finalize detailed project estimates

- Estimate delivery, installation, and training timeline

- Prepare return on investment model

Phase Deliverables:

- Finalize layouts demonstrating overall project concept, cost, timelines and return on investment

- Full document package to be delivered in Adobe® PDF format

4. Project Execution

- Provide full project management including supplier coordination

- Final review of design, cost and timelines

Phase Deliverables:

- Start-up coordination and support

- Provide training plans and all necessary manuals

- Equipment procurement assistance including recommended spare parts list

The many benefits of Volm VEST solutions

Our VEST specialists work tirelessly to:

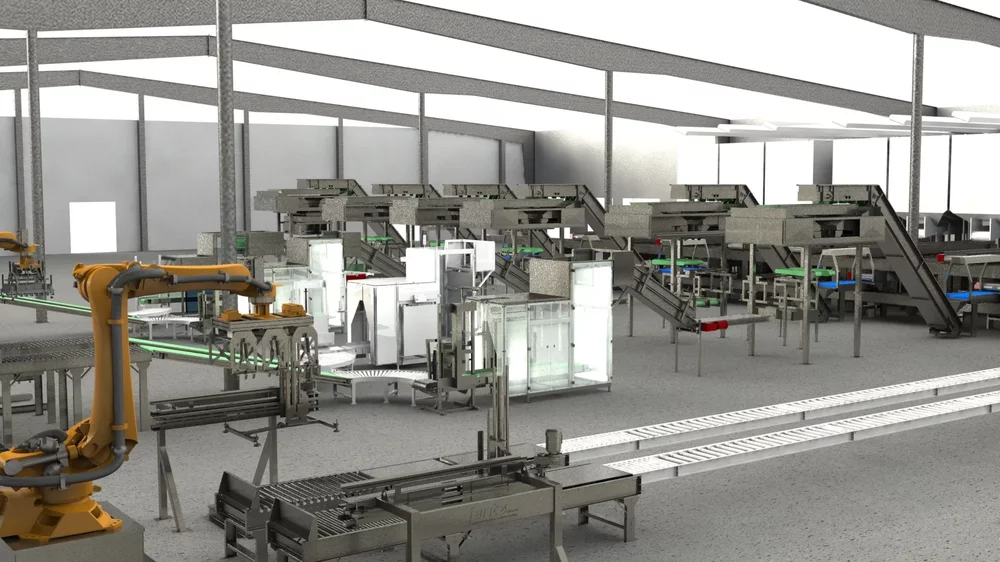

- Reduce labor costs through automation including robotics

- Improve safety

- Increase throughput and productivity

- Remain compliant with the industry's increasing demands for fresh produce traceability and safety

- Lower rejection rates through better handling and weighing

- Streamline operations and production processes

The Only Single Source, Full Line Integration Provider

As the only vertically integrated packaging and equipment manufacturer and distributor in the industry, we understand how to bring together the disciplines of design, collaboration, innovation, engineering, integration, and ingenuity and turn them into production solutions that can turn profits.

Whether it's an entire production solution or an upgrade to existing workflows, the Volm Engineering Solutions Team works to maximize your productivity in Receiving, Grading, Packaging, Palletizing, and Material Handling.

Best of all, Volm Companies stands behind every product solution we sell, and we back that up with a commitment to service that continues for the life of your equipment.

Let us help you build your next success—with Volm VEST.

Let us show you with a no obligation Project Request evaluation. Call 888-349-8656 for details.

VOLM VEST Success Story

VEST completed an extensive project with Mart Produce of Rupert, Idaho to build a state-of-the-art automated facility.

According to Jeff Harper, President "The new state-of-the art packing facility increases production by 50% and at full capacity, we estimate labor savings up to 30% annually."