Image

Volmstack Robotic Systems for Cases, Cartons & RPCs

The Volm Companies robotic solutions team has designed numerous robotic palletizing cells that are able handle a wide range of products, including cases, cartons and RPCs. Our flexible robotic palletizing systems can be programmed for high-speed stacking or display-ready presentations. The systems are available in several sizes to accommodate a range of product flow from the packing line.

Most Common Uses

- Apples

- Carrots

- Citrus Fruits

- Garlic & Shallots

- Onions

- Potatoes

Robotic Palletizing Solutions

Product Detail

Features

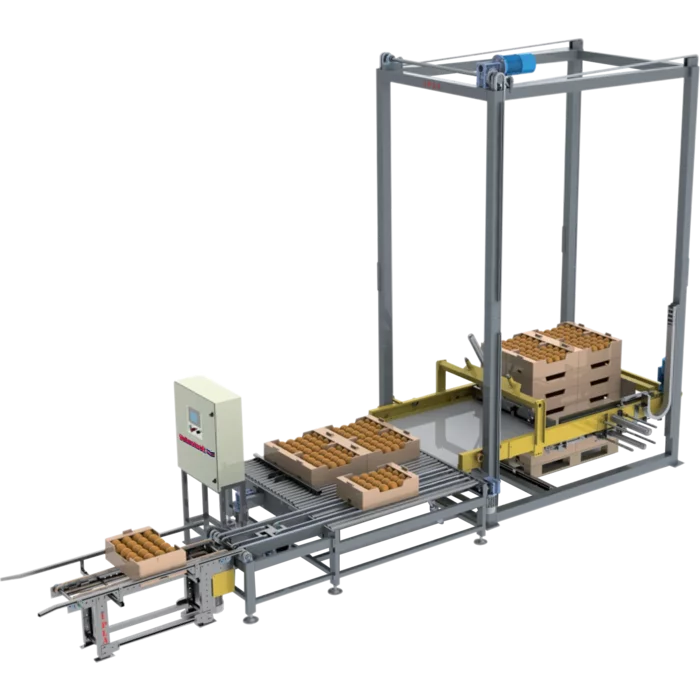

- Small palletizing systems for cases have single-lane infeed, single-lane stacking, and allow for operators to easily remove each full pallet by pallet truck or forklift

- Medium palletizing systems for cases have dual-lane infeed, dual-lane stacking and pallet dispensing. They typically include some manner of pallet handling conveyors to increase the level of automation.

- Large palletizing systems for cases have tri-lane infeed, tri-lane stacking, dual pallet dispensing and slip-sheet dispensing or quad-lane infeed, quad-lane stacking, dual pallet dispensing and slip-sheet dispensing.

- The robot is able to continually stack cases on the pallet loading areas; then they are released when pallet is full for operator to remove (small systems), or directly to the pallet discharge conveyor (medium & large systems)

- Single pallet dispensers for continuous flow of pallets to robot loading area (medium & large systems)

- Dual pallet dispensers can be programmed to use different pallets to fill customer requests for specific pallet type (ie. CHEP Pallets) (large palletizing systems)

- Automated slip-sheet depositor will help reduce labor costs and can be programmed to deposit slip-sheet to required orders only (medium & large systems)

- Light curtains let the full pallets of product leave while the robot continues to palletize more product (small, medium & large systems)

- The safety fencing is to protect employees, still letting them monitor the robot’s operations while meeting all safety standards of local labor laws. (small, medium & large systems)

- Easy-to-access HMI (Human Machine Interface (small, medium & large systems)

Available Options

Speed

Small palletizing systems:

- 3 pick case end of arm tool, 20 to 24 cases per minute*

- 4 pick case end of arm tool, 22 to 28 cases per minute*

Medium palletizing systems:

- 3 pick case end of arm tool, 20 to 24 cases per minute*

- 4 pick case end of arm tool, 24 to 28 cases per minute*

Large palletizing systems:

- 3 pick case end of arm tool, 20 to 24 cases per minute*

- 4 pick case end of arm tool, 22 to 28 cases per minute*

or

- 3 pick case end of arm tool, 18 to 22 cases per minute*

- 4 pick case end of arm tool, 20 to 26 cases per minute*

Specifications

Small palletizing systems for cases:

- Minimum floor space required: 22’ 11” W x 28’ 7” L (7m W x 8.7m L)

Medium palletizing systems for cases:

- Minimum floor space required: 33’ 3” W x 19’ 11” L (10.1m W x 6m L)

Large palletizing systems for cases:

- Minimum floor space required: 32’ 1” W x 38’ L (9.8m W x 11.6m L)

Brochures & Product Documents

Ordering

To order call 1-800-253-4737 or email equipment@volmcompanies.com