Image

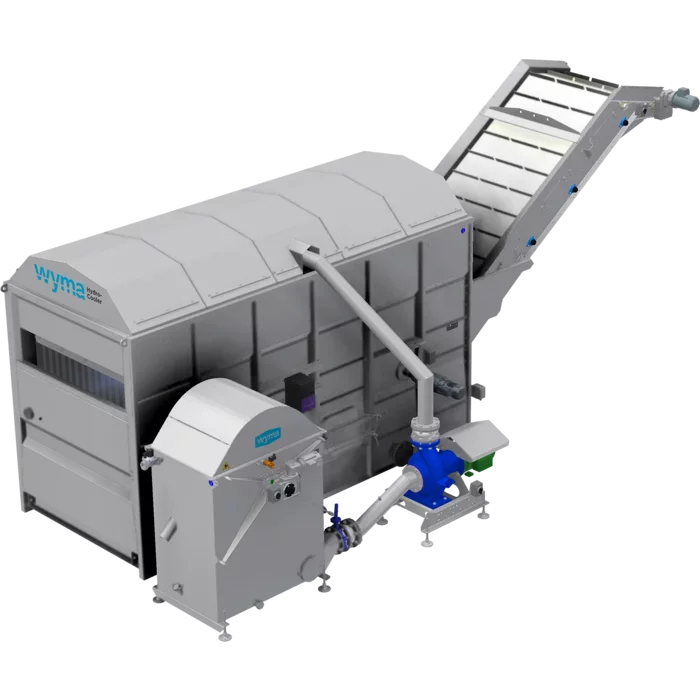

Bunker

The Bunker is a dry hopper. It receives and stores produce for automatic, controlled delivery to processing lines. Each Bunker can hold up to 50 tons of produce and can process up to 25 tons an hour. There are two types of Bunkers. A fully closed Bunker is a large storage hopper with four walls; multiple bunkers can be assembled in line to meet specific needs. And a side-receiving Bunker has an open side so produce can be unloaded from a truck or other unloading system. This has reduced capacity but still provides buffer storage.

Most Common Uses

- Carrots

- Onions

- Potatoes

Product Detail

Features

- ‘First in, first served’ system - produce at bottom of bunker is carried to outfeed

- Mild steel galvanized and painted or upgrade to durable 304 stainless steel construction

- Ribbed frame and tall tank for strong holding capacity

- V-shaped floor regulates produce flow to conveyor

- Turkey roost prevents weight accumulation on belt

- Heavy duty conveyor belt running on a roller bed

- Single or multi-stage soft drop system minimizes produce damage on loading

Available Options

Infeed Options

Speed

- Can process up to 25 tons an hour

Ordering

To order call 1-800-253-4737 or email equipment@volmcompanies.com for more information.