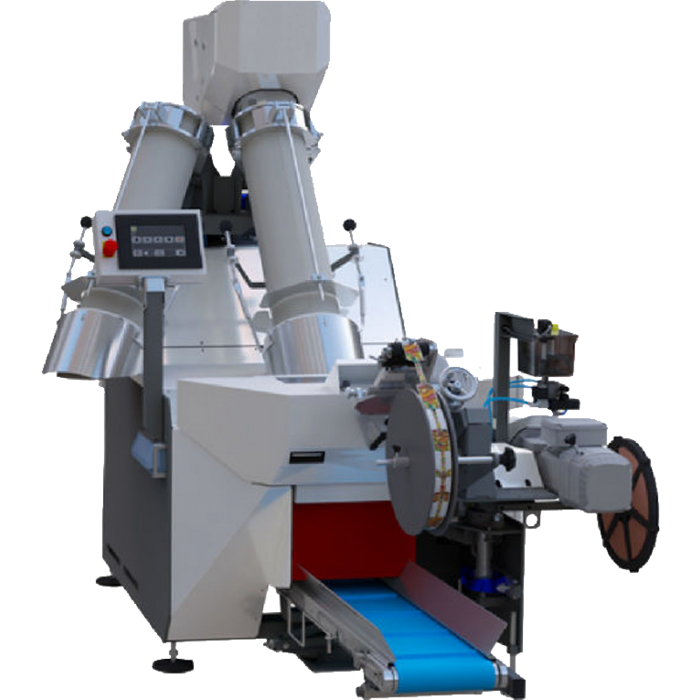

Volmpack Clipper M3

The Clipper M3 automatically packs product into tube netting, closing the netting with metal clips. The Clipper M3 is equipped with an automatic tube exchange to ensure a continuous supply of netting while the tube netting is refilled.

The Clipper M3 can be used with either extruded or knitted mesh products. The extensive tube diameter range allows facilities to package for industrial and consumer applications. At up to 55 bags per minute, packing facilities can keep up with the consumer demands.

- Citrus Fruits

- Garlic & Shallots

- Nuts

- Onions

- Potatoes

- Seafood

Volmpack Clipper M3

Features

Flexible metal clipping system to allow for a wide range of wire thicknesses while maintaining the complete closure and label attachment on every bag Clipper mechanism has limited wear parts to ensure a long working life Accepts both extruded and knitted mesh materials Integrated labeler works with both wine glass and strip labels and can easily switch for different packages.

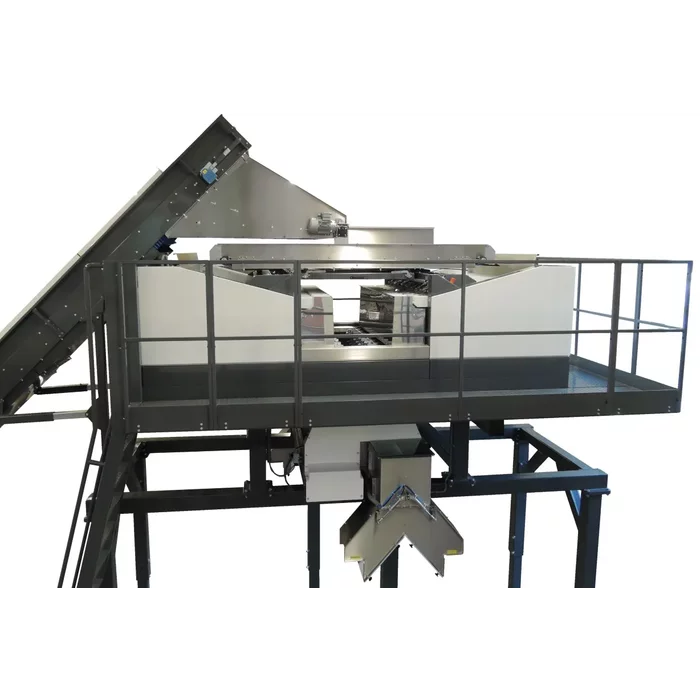

Automatic tube exchange to continue operation while tube netting is refilled.

Available Options

Compatible Equipment

- Volmpack M8

- Volmpack M10

- Volmpack MD12

- Volmpack M12 V

- Volmpack MD16

- Volmpack MD16D

- Volmpack MD 20

- Volmpack M2i V

Package Size Range

1 to 5 lbs

Speed

- 1 pounds up to 55 packaging per minute*

- 5 pounds up to 40 pouches per minute*

Disclaimer:

* Depends on product, infeed, and discharge system.

Specifications

- Air Consumption: 1.8 CFM**

- Power: 230 Volt, 3 Phase and Ground

Disclaimer:

** Actual air consumption will increase based on the discharge system(s) chosen.

Brochures & Product Documents

Ordering

Call 1-800-253-4737 or email equipment@volmcompanies.com for more information.