Image

Roll-Back Bin Tipper

The Roll-back Bin Tipper is a corner pivot tipper designed for gentle, regulated produce tipping. It is usually sold with a conveyor or small hopper to receive tipped produce. A bin is placed on the cradle platform. The tipping cycle is activated and the bin lifts slightly to clamp against the roll-back lid. Hydraulic cylinders tip the secured bin to the full tip position. The lid partially opens to gently release produce. When the bin is empty, it returns to the start position ready to be removed by forklift. This system is fully automated to minimize processing or bagging delays.

Most Common Uses

- Carrots

- Citrus Fruits

- Garlic & Shallots

- Melons

- Onions

- Potatoes

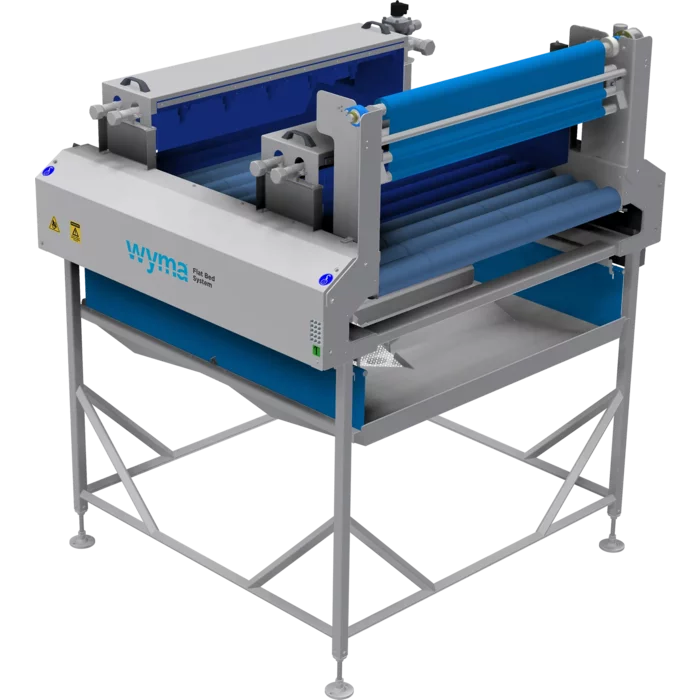

Wyma Roll-back Bin Tipper

Product Detail

Features

- Automated hydraulic bin clamp

- Custom frame heights to integrate the tipper into processing lines

- Durable and robust design

- Stainless steel construction in high wear areas

- Roll back lid to discharge produce

- Photoelectric sensor system to control product discharge

- Long stroke cylinders allowing tipping through 140 degrees

- Quick operation (as little as 25 seconds per bin) Siren and warning lights to enhance safety

- Can handle multiple bin sizes

Available Options

Speed

- 25 seconds per bin, tipped and returned

Brochures & Product Documents

Ordering

To order call 1-800-253-4737 or email equipment@volmcompanies.com for more information.